From Airflow to Innovation: A Laboratory Ventilation Risk Assessment in Action

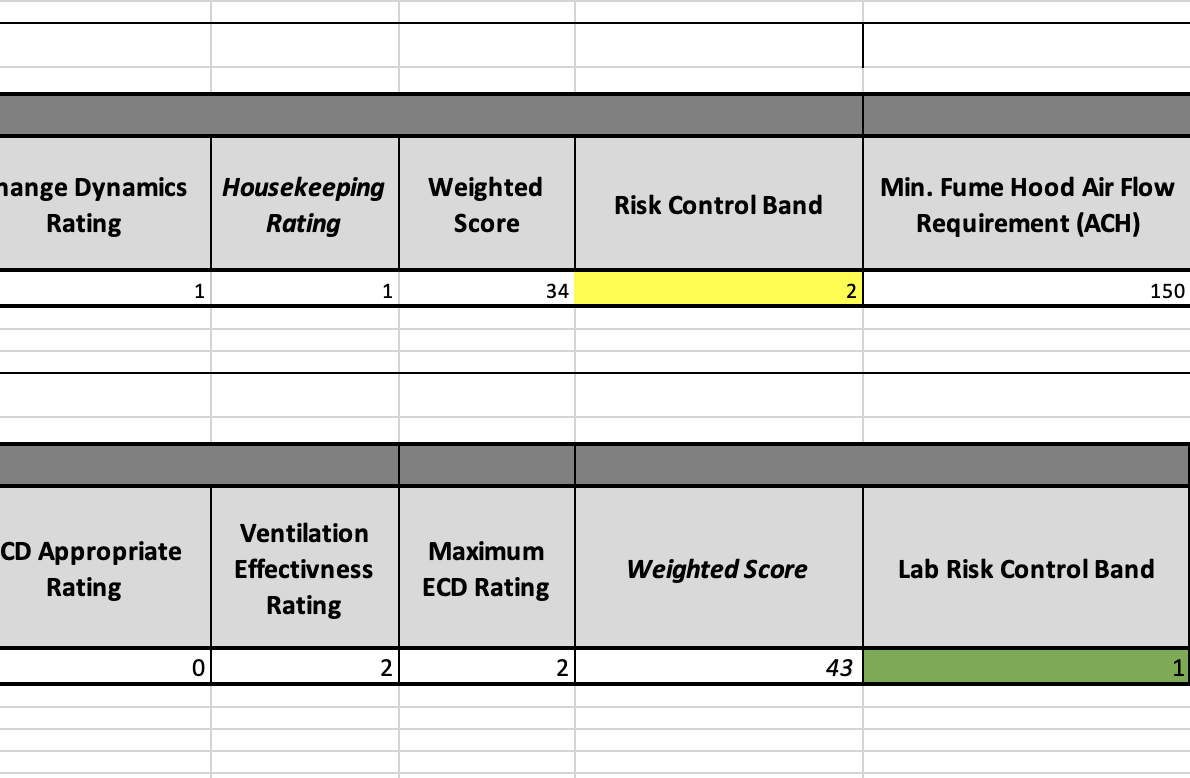

Documentation of risk control band values for exposure control devices (ECDs) and laboratory environments using the LVRA tool. For more information, refer to the LVRA section under Assess and download the user guide.

When planning laboratory renovations or designing new facilities, project teams have an opportunity to move beyond traditional approaches that rely on pre-set ventilation values. By evaluating ventilation requirements specific to the unique needs of the laboratory space, they can ensure the system is both effective and efficient.

Industry partners Cator Ruma & Associates and Hord Coplan Macht collaborated to renovate and upgrade laboratories in a university building constructed in the 1970s. The renovation supported green chemistry initiatives, improved operational flow, and enhanced safety and efficiency. A key aspect of the project was the use of a laboratory ventilation risk assessment (LVRA), which supported the design and operational upgrades of the laboratories.

Laboratory Ventilation Risk Assessment

An LVRA is a structured process that helps lab designers, heating, ventilation and air conditioning (HVAC) engineers, and laboratory safety personnel assess risks in the lab. The 2018 LVRA User Guide outlines a collaborative process involving facility managers, research staff, environmental health and safety professionals, and industrial hygienists to set laboratory ventilation requirements based on hazards in the lab space.

The LVRA process draws on tools and guidelines from the Smart Labs Toolkit, including:

- Exposure control device evaluation

- Laboratory environment evaluation.

While the LVRA categories differ across these sections, both evaluate factors such as:

- Hazard exposure

- Hazard quantity

- Generation rate

- Generation method.

Once these criteria are assessed, risk control bands can be assigned to laboratory areas in design. This can be done by applying predefined risk design levels based on ASHRAE’s Classification of Laboratory Ventilation Design Levels or by analyzing known or anticipated laboratory use and future scientific activities.

These insights help establish ventilation demands and provide tailored recommendations to support safe and efficient laboratory operation in both new and existing spaces.

Laboratory Ventilation Risk Assessment in Action

Using scenarios provided by the university, the LVRA tool was used to simulate operational and hazard conditions within the laboratory spaces. A key aspect of this process, emphasized by Cator Ruma & Associates and Hord Coplan Macht, was early and consistent engagement with laboratory users, building owners, and faculty managers.

Collaborative meetings provided valuable insights into lab operations and potential risks, while user surveys helped identify worst-case scenarios based on the types of hazards, quantities, and workflows involved. These efforts laid a solid foundation for developing the evaluation criteria used in the LVRA.

The project team focused on three criteria for the laboratory environment, which the tool calculates with the greatest sensitivity:

- Hazard exposure limit

- Potential rate of generation

- Ventilation effectiveness.

According to a senior mechanical engineer at Cator Ruma & Associates, completing the LVRA is an iterative process requiring continuous refinement as more data becomes available. All possible scenarios must be assessed to determine the worst-case. For example, one scenario could have a large quantity of a low-hazard material while another has a small quantity of a high-hazard material. Each must be evaluated to determine which scenario drives the ventilation requirements. Variables such as change dynamics, laboratory cleanliness, and exposure limits, were particularly challenging to define given the complexities of the laboratory settings.

Before the LVRA assessment, the teaching laboratories operated at 16 air changes per hour (ACH) during both occupied and unoccupied periods. Up to three exposure control devices were used in each laboratory.

Using the LVRA User Guide and calculated LVRA data, the team determined that reducing ventilation to six ACH during occupancy and two ACH when unoccupied would best balance safety and energy efficiency. Occupancy was monitored using sensors within the lighting systems.

In addition to optimizing ventilation, the renovation project incorporated several infrastructure upgrades to improve energy performance:

- Converting the constant air volume system to a variable air volume system

- Installing an energy recovery system with run-around loop design

- Adding fan coil units to decouple cooling from ventilation air.

Despite only renovating 1.5 of the building’s five floors, these improvements resulted in a 20% reduction in energy use intensity. Future upgrades to convert additional constant volume labs to variable volume with decentralized cooling could achieve projected reductions of nearly 40%. These changes not only improved energy efficiency but also aligned the laboratory spaces with modern safety and operational standards.

This project highlights how the LVRA process, combined with collaborative design, can transform outdated laboratory facilities into safer, more efficient spaces. By aligning ventilation strategies with project goals, the teams reduced energy use while improving safety and performance. The LVRA tool provides a dynamic framework for managing the laboratory environment.

When applied consistently and updated regularly, LVRA helps maintain optimal ventilation, adapts to changes in laboratory use, and addresses evolving scientific activities. This proactive approach supports continuous improvement, making the LVRA a powerful tool for achieving both environmental and operational excellence throughout a laboratory’s lifecycle.

Lessons Learned

- Stakeholder engagement is critical: Early and consistent collaboration with laboratory users and stakeholders ensures accurate data collection and informed decision-making.

- Iterative process: LVRA requires adjustments and refinements as new data and variables emerge.

- Criteria evaluation: Factors such as chemical dilution, method of generation, and exposure limits require careful evaluation and may vary between laboratory settings.

- ACH optimization: Achieving the right balance of ventilation rate for occupied and unoccupied periods supports safety and energy efficiency goals.

- Integrated design approach: Combining LVRA findings with infrastructure upgrades can lead to significant improvements in energy performance and overall laboratory functionality.