The Optimize phase involves executing the scope of work proposed in the Assess phase through appropriated funds of financing mechanisms. Laboratory buildings vary in age, size, function, and type of systems. Depending on the state of the systems, safety objectives, energy goals, and available funds, optimization projects can range from implementation of simple, no or low cost measures to full scale renovation of buildings involving highly complex and costly measures. This part of the toolkit includes guidance on:

- Project funding and bidding process

- Implementation of improvement measures, from large scale renovations to simple upgrades

Project Funding

Where the scope of the project exceeds available funds or annual budget allowance, utility incentives and other funding sources such as energy saving performance contracts may be available to assist with project execution. In some cases, it may be feasible to prepare a strategic project plan that executes the work over multiple years to leverage annual budgets while still achieving the end objectives in a predictable, yet extended timeframe.

Third-party financing strategies for energy projects are a proven cost-effective procurement pathway. There are several procurement mechanisms available for third-party financing of energy projects. The two most widely used are: energy savings performance contracts (ESPCs) and utility energy savings contracts (UESCs). ESPCs and UESCs can also be used to fund water efficiency projects. Where traditional funding authorities do not exist, there are alternative funding approaches such as public-private partnerships to consider.

The following are brief descriptions of the various procurement mechanisms for financing projects.

Up-front Capital or Internal Funding

Energy projects can be funded directly through the organization's budget mechanisms. It is important to know that the life-cycle costs of internally funded projects versus ESPC contracts have been shown to be approximately the same, if all costs and the longer time cycle of appropriations funding are included in the cost considerations.

Federal and State Incentives

The presence of federal and state incentives for energy efficiency, renewable energy, and microgrids can be a key driver of a project's economic viability and can serve as a helpful screening heuristic. Energy projects at a site may also be eligible for utility rebates.

Energy projects owned by a third party with tax liability could be eligible for federal tax and accelerated depreciation incentives. In addition, a site may also choose to sell the renewable energy credits (RECs) or Solar RECs (SRECs) to accrue significant value for such projects. For example, some states such as New Jersey have lucrative SREC markets that could provide additional value to a resilient energy project. For additional information on incentives see the Database of State Incentives for Renewables & Efficiency (DSIRE).

Bonds

Higher education institutions are starting to use bonds to finance construction projects. For example, in the U.S. Department of Energy Better Buildings Showcase Project: Smart Labs Initiative/Natural Sciences II, energy bonds used to finance the projects are repaid with savings from the utilities budget at no additional cost to the university.

Energy Savings Performance Contracts (ESPCs)

The Better Buildings ESPC Toolkit is a collection of resources to enable state and local communities to benefit from the experience of partners who have successfully established and implemented performance contracting. It includes best practices and innovative approaches that states, cities, and K-12 schools have used. Users can easily find the information they need at each stage of their ESPC decision-making process.

Energy Savings Performance Contracts (ESPCs) are executed by Energy Service Companies (ESCOs) to enable agencies to undertake energy-saving projects without the need for upfront capital costs or special appropriations. By leveraging the ESPC mechanism, agencies can integrate existing deferred maintenance and project budgets more effectively. A project budget may cover only part of a project or may not be the most efficient, the ESPC allows agencies to “buy down the cost” and then finance the remaining balance to optimize the efficiency of the project. The ESPC also offers a competitively bid contracting mechanism and really greases the wheels and gets projects implemented faster with less hassle for the agency. By incorporating an ESPC into capital planning processes and laboratory projects, agencies can benefit from a comprehensive solution that includes project development, design, financing, implementation, and ongoing measurement and verification (M&V). In consultation with the organization, the ESCO designs and constructs a project that meets the agency's goals and arranges the financing, paid for by efficiency measures. This arrangement ensures that the project is tailored to the specific requirements of the laboratory setting while securing the funds needed for implementation.

Best practices recommended for ESPCs include the following:

- Because of the complicated nature of labs, the organization should staff support for the investment grade process (IGA). ESCO’s typically have general expertise, but the organization will need to bring experience on how labs work.

- To properly implement an ESPC in a laboratory setting, it is crucial that lab stakeholders from the organization are familiar and engaged with the ESPC/ESCO processes. Their engagement and support are vital to achieving the overall project goals. Engaging research staff early through assessments such as a Laboratory Ventilation Risk Assessment (LVRA) can provide the necessary expertise to apply new energy-saving measures effectively in the laboratory environment.

- The LVRA should be completed prior to engaging the ESCO. By completing the occupant engagement, safety checks, and more during the LVRA process, this information can give the ESCO confidence to implement air change rate improvements.

- For campuses, integrate the ESPC plans into the capital planning process of the site. This ensures that the ESPC measures are not in conflict in the future with major campus new construction or renovations.

Optimizing Ventilation for ESPC in Labs:

Ventilation efficiency is a crucial aspect of laboratory design, essential for ensuring safety, reducing energy consumption, and maintaining proper environmental conditions. Efficient ventilation systems in laboratories are vital to meet specific program requirements while optimizing operational costs.

Key Strategies:

- Verify Use of Program-Specific Setpoints: Ensure that ventilation systems are configured to meet the precise needs of different lab programs, avoiding unnecessary energy use.

- CAV to VAV Conversions: Converting Constant Air Volume (CAV) systems to Variable Air Volume (VAV) systems allows for flexible and efficient airflow management based on real-time demand. Although this transition may be gradual, it allows for setting the ventilation to the lowest safe rate as determined by a LVRA.

- Layout Ventilation Equipment for Efficiency: Strategically place ventilation equipment to maximize coverage and efficiency, reducing the energy required to maintain proper airflow.

- Provide Specialized Solutions: Implement solutions for ventilation-heavy or temperature-sensitive programs to localize control and minimize the load on the main HVAC system.

- Design Equipment for Low Pressure Drop: Select and design ventilation components that minimize pressure drop, enhancing system efficiency and reducing energy consumption.

- Model Exhaust Stack Design and Size Appropriately: Accurately model exhaust stack design requirements to ensure systems are properly sized, optimizing performance and efficiency.

- Separate Thermal from Ventilation Control: Distinguish between thermal and ventilation needs to fine-tune each system independently, improving overall efficiency and comfort.

- Use Good Control Practices: Implement best practices in ventilation control, such as demand-controlled ventilation and regular maintenance, to sustain efficiency and performance.

Measurement and verification (M&V) are essential components in the implementation of an ESPC, ensuring that the energy savings are accurately tracked and validated. Effective M&V can significantly enhance project outcomes, but careful consideration is required to confirm that the chosen M&V approach is both appropriate and reasonable. Implementing M&V can be rigorous and challenging, especially within the first year. An ESPC begins with energy audits conducted by the energy service companies, which provide recommended M&V practices to support project success. Over time, ESPCs may encourage the host customer to pursue less intensive M&V as they assume financial responsibility.

By following these steps and involving the appropriate stakeholders, an ESPC can significantly enhance energy efficiency in laboratory settings, leading to reduced energy costs and improved sustainability.

Take Action: Key Lessons Learned for Implementing ESPCs in Labs

Implementing Energy Savings Performance Contracts (ESPCs) in laboratory settings can be highly effective, but careful planning and engagement are essential for success. Key actions based on lessons learned include:

- Engage and communicate WITH relevant stakeholders early

- Complete a Laboratory Ventilation Risk Assessment prior to engaging the ESCO

- Integrate ESPC in Capital Planning

- Focus on Measurement and Verification (M&V)

Utility Energy Services Contracts (UESCs)

Another funding mechanism for agencies to implement efficiency and renewable energy projects is through utilities. Agencies often enter UESCs to implement energy improvements at their facilities. With a UESC, the utility typically arranges financing to cover the capital costs of the project. The agency repays the utility over the contract term, drawing on the cost savings that the energy efficiency measures generate. Using this arrangement, agencies can implement energy improvements with no initial capital investment; the net cost to the agency is minimal, and the agency saves time and resources by using the one-stop shopping service provided by the utility.

Power Purchase Agreements (PPA)

PPAs allow agencies to finance on-site renewable energy projects while incurring no up- front capital costs.

With a PPA, a developer installs a renewable energy system on agency property under an agreement that the agency will purchase the power that the system generates. The agency pays for the system through these power payments over the life of the contract. After installation, the developer owns, operates, and maintains the system for the life of the contract.

Implement Improvement Measures

Performance improvement measures are intended to enable safe, efficient, and sustainable systems. Measures can include upgrading fume hood performance, implementation of advanced sensors, variable air volume (VAV) controls, demand control ventilation, and use of efficient fans and mechanical system components. All systems and components are subject to testing, adjustment, balancing (TAB), and commissioning. Implementation strategies for measures vary depending on the level of effort of the project. There are three levels of improvement measures: low-effort, medium-effort, and high-effort. Each of these levels is described briefly in the table below, including lists of examples.

| Low-Effort Measures: Tuning, Small Tweaks, and Adjustments |

|---|

These measures involve minimal to no funds and require little effort to ensure that all systems and components are calibrated and tuned to function properly. TAB and commissioning are included as a combined effort to:

|

| Medium-Effort Measures: Minor Repairs, Replacements, and Upgrades |

These measures involve minimal investment to implement. Many upgrades can be completed by in-house personnel; however, some may require minimal contractor commissioning. Medium-effort measures include:

|

| High-Effort Measures: Entire System Renovation, Modification, and Construction |

These measures involve significant funds, contractors, and commissioning for complete system renovations. They also require significant effort for project management. High-effort measures include:

|

Additional details on specific improvement measures are include in the HVAC resource map.

Project Management

Owner/Lab Manager Project Management

Labs are constructed for those who occupy and work within the space—and the space exists for only one reason: to support the researcher. Deficiencies in infrastructure, design, or construction can prevent the laboratory from fulfilling its purpose. Managing the effect of the project on lab activities is often delegated to a lab manager who may be inexperienced or unfamiliar with the myriad of technical requirements unique to labs. Lab management experience doesn't always prepare one to maximize the results of a lab renovation.

It is essential that the owner's lab representative be involved in the pre-planning, planning, and design phases so that when construction is initiated, the team members are fully invested in the process and have a clear understanding of the goals and objectives of the project. At a minimum, the lab manager will play a critical role as head of the users' group.

Construction/Renovation Project Management

Project managers may arise from different backgrounds, but they must be skilled in sensibly balancing end user needs with top management desires for on-time schedule completion and budget control.

There are four critical success factors for effective construction project management in labs:

Process: The process must be well defined and articulated to be understood by all participants. The plan must be comprehensive from pre-design through post-construction.

Communication: Clear lines of communication and clear lines of authority are essential and should be comprehensively defined from pre-design through post-construction.

Champion: The champion is someone who can articulate the need for the project, drive progress, and remain committed to the success of the project. There must be a direct line of communication to the administration, and the champion should have the confidence of stakeholders including users and administration. The champion should be with the project from start to finish.

Design Professional: The selection of the design professional is critical to the success of the project because this individual usually recommends the participation of others including engineers and specialty consultants. The design professional should be able to demonstrate successful completion of at least one project of similar scale and in a relevant scientific area.

Contractor Selection

Finding the right contractor with good laboratory experience within the project budget can be a daunting task. Each organization may have its own process for selecting a contractor for specific projects. In any case, discuss the balance between quality of work and cost carefully with the Smart Labs team and laboratory stakeholders to determine the best contractor for the project's needs.

Develop Engineering Design Specifications

Design, installation, and modification of systems requires an engineering effort to produce specifications, drawings, and other information necessary to implement the performance improvement measures. The effort may include developing detailed plans for installation, replacement of components, system upgrades, testing and balancing, and commissioning. The engineering plans and specifications also include project management, coordination of efforts and schedules to achieve project goals.

Example Engineering Design Specifications

When developing design specifications for the laboratory building systems, it is useful to draft detailed documentation containing specific system requirements. These documents specify how the building's ventilation system will be managed and operated, with exact setpoints and airflows explicitly defined to maintain continuity between all parties involved. The following group of documents from the University of New Hampshire provides examples of such documentation and can be used to model the engineering specifications and system requirements. The documents span from instrumentation and controls requirements for a BAS to detailed guides for configuring graphics for reports and analysis of system performance.

See the University of New Hampshire Planning, Design, and Construction Guidelines.

Optimize Operations

Commissioning

Commissioning: "The process of ensuring a building's operating systems—mechanical, electrical, HVAC, etc.—are designed, installed and programmed for optimal performance."

Retrocommissioning is the application of commissioning to existing buildings, reviewing the building's systems and ensuring that systems are working as designed and in application.

Retrocommissioning vs. Recommissioning

Photo credit: Dennis Schroeder / NREL

Retrocommissioning is for buildings that have not undergone commissioning before, or were improperly commissioned, while recommissioning is for buildings that have been commissioned previously. Both types of commissioning seek to optimize the building's performance and enhance efficiency of the existing systems.

It is important to note that recommissioning to original design standards and specifications may not be appropriate as the functional requirements and operating criteria of the building occupants have changed. The demand for air and/or physical changes to the spaces may have changed, requiring the development of new airflow specifications.

There are five steps to the standard commissioning (Cx) process.

- Preconstruction

- Review owner's requirements

- Design reviews

- Develop Cx plans and specifications

- Construction

- Finalize Cx plan and schedule

- Develop test procedures

- Monitor issues/resolutions log

- Acceptance

- Review TAB reports

- Participate in functional testing

- Review operations and maintenance (O&M) manuals

- Implement plan for training

- Hand-over

- Finalize training

- Deliver final Cx report

- Deliver system manual

- Occupancy

- Operations procedures manual

- Periodic O&M review

- Maintenance contractor training

- The Cx will be familiar with the standard operating procedures (SOPs) established by the lab and assure the building's performance criteria are installed to perform in concert with the SOPs

- The Cx develops criteria and scenarios to simulate real life situations that could cause an outage or planned or unplanned system failures, to ensure that the systems will all work together in different failure and maintenance scenarios

- Construction and renovations should be verified to ensure quality and fitness for purpose

- Creation of a detailed Cx plan

- O&M documentation and training is provided to ensure the client group can manage the building systems

- Accurate and complete as-built diagrams to ensure long-term success

- Validation should include a post-occupancy evaluation approximately 1 year following completion as some problems don't become immediately apparent

Ongoing commissioning is a type of recommissioning where the process to ensure adequate building performance is done on a continual basis. The collection of data analytics on laboratory systems makes ongoing commissioning possible through their organization on energy management information system platforms, which are discussed in the next section. Ongoing commissioning programs enable organizations to quickly identify equipment deficiencies as they occur and fix them to ensure their proper operation, maintaining an organization’s long-term energy savings.

Test and Balance Labs

HVAC Testing, Adjusting and Balancing (TAB) contains the three major steps used to achieve proper operation of HVAC systems. TAB applies to both air and hydronic measurements and adjusts flows required to achieve optimum performance. TAB is based on design flow values produced by the mechanical engineer. Following completion of the TAB process, the TAB contractor supplies a written report containing the final flow values, and notes any deficiencies found during the TAB process.

Conducting TAB is almost always a component of a laboratory optimization project. New airflow specifications may require adjustment to dampers and valves. Testing sensors, airflow stations and other devices identify defective components requiring repair or replacement. TAB personnel are often used to collect pre- and post-optimization air and water flows for benchmarking system performance for use in the laboratory ventilation management program.

TAB specifications and SOPs for laboratories and other critical workspace environments may differ from standard commercial applications. In typical commercial buildings, a tolerance of ±10% for airflow at the device level is acceptable. For critical workspaces, a tolerance of ±5% is desired to fall more in line with precision requirements for exposure control or other devices. Lab differential pressurization criteria also demand closer tolerance to design airflows to ensure proper pressurization during all HVAC system operating modes (e.g., occupied or unoccupied).

Establish New Baseline through Benchmarking

Following establishment of proper calibration and functioning of all systems and components, the systems are challenged to verify performance over the range of expected operation. It is important to document and benchmark final operation parameters in order to measure and verify energy savings.

Continuous Improvement with Energy Management Information Systems (EMIS)

Data Analytics with Energy Management Information Systems

An energy management information system (EMIS) is comprised of devices, data services, and software applications that monitor, analyze, and control metered building energy use and system performance. Elements of an EMIS work together to aggregate facility data and help federal energy managers optimize energy use at the building, campus, or agency level. For more information on what an EMIS is, FEMP has provided a webpage with additional information, which can be found here.

Integration and AFDD

Nearly all building utility data can be integrated into an EMIS, including all building automation system (BAS) points: laboratory control system data, lighting systems, temperature and humidity sensors, utilities, room scheduling, and more. In a laboratory, conditions cannot be managed if they are not measured, therefore an EMIS is essential for continuous improvement and optimization of all technology and equipment. Setting a baseline is important for understanding when systems in laboratories aren’t working properly or optimally. With the addition of automated fault detection and diagnostics (AFDD), which is typically an additional feature within EMIS, a software system can alert users when labs are not operating properly. With customization for fault parameters to ensure safety in the lab, a user can monitor all systems actively promoting efficiency in a safe fashion.

Human-in-the-Loop and Operations

An EMIS with AFDD is a human-in-the-loop tool, meaning the software actions require human interaction. An EMIS will allow users to establish baselines and understand where improvements can be made; however, facility staff operational processes must enable these features. In some workplaces, it is critical to make facility teams aware and empower the team to make changes based on the EMIS data. This is especially important in relation to laboratories to keep staff safe along with knowing there are proper air change rates, temperatures, and humidity conditions.

The power of EMIS allows for energy resilience and project security. Energy resilience is offered in numerous ways, for example, having visibility into when a power source may become unreliable to ensure there is no energy interruption. This enables project security to know all environments stay consistent and safe. With this, energy savings and system optimization are possible.

Throughout implementation of improvement measures, resilient strategies should be included wherever possible. See the Resilience section in Assess. Successful projects in labs can be opportunities to learn more about which resilience strategies work best for your particular lab. For more information, check out the case study on Implementing Occupancy Sensors in Labs.

Examples

Where an EMIS is implemented, the lab has experienced condition improvements and other benefits such as:

- Facility and utility dashboard for energy management

- Energy reporting capabilities

- Building operations and controls improvements

- Building systems fault detection and diagnosis

- Central plant operational improvement, reducing cost and energy

- Electrical distribution system operations improvements offering greater visibility and readiness

- Fault detection and diagnosis for laboratory directed research and development projects

- Energy Systems Integration Facility tenant billing

- Energy resilience and flexibility

- Lowering energy sue from airflow without affecting occupant safety

Continuous Improvement

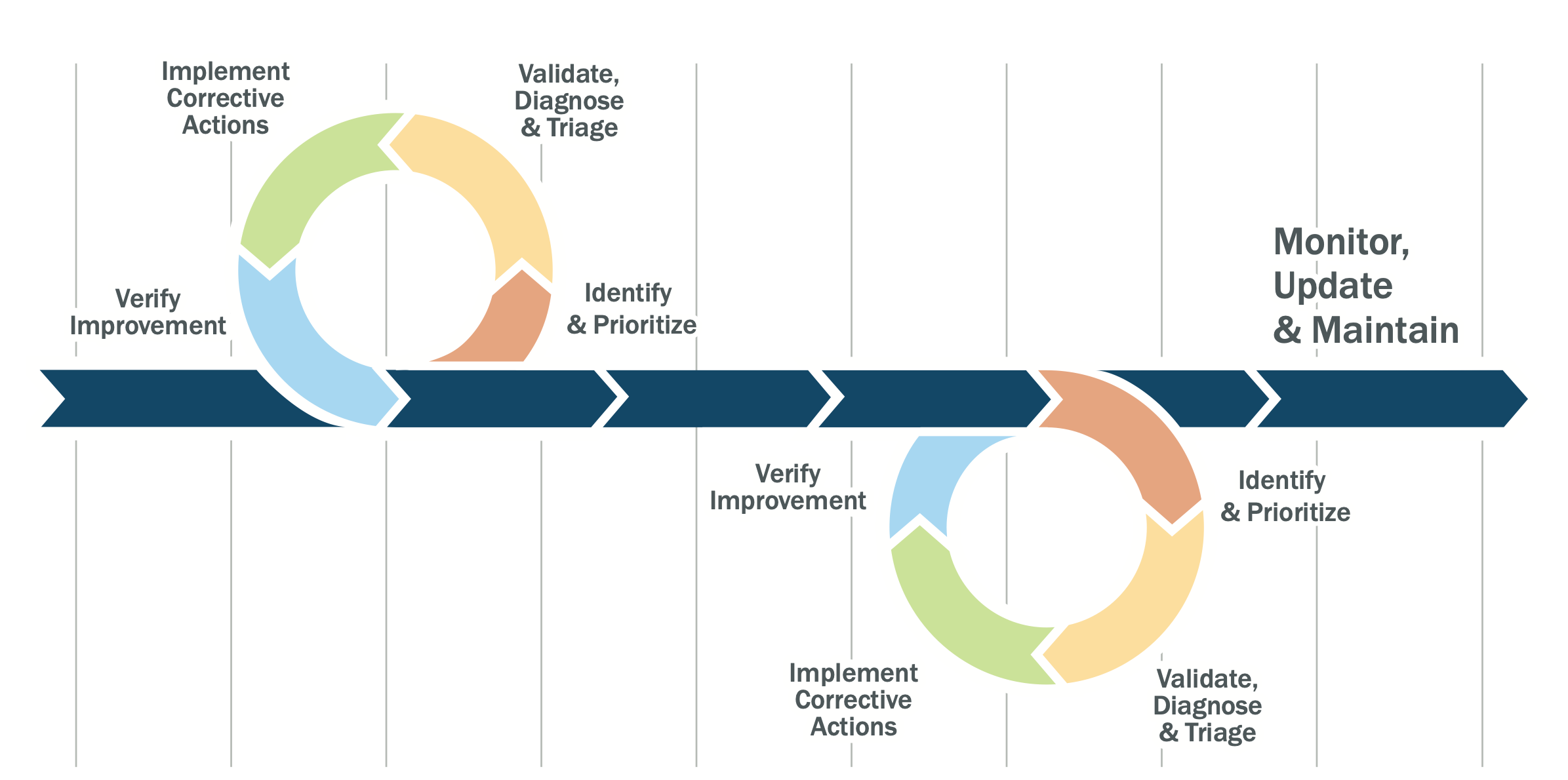

EMIS allows for continuous improvement enabling energy and cost savings. The continuous improvement process should be implemented along with the EMIS. Following proper calibration and functioning of all systems and components, energy and system operation baselines can be established. Once these are established, corrective measures can be made. After equipment or operational changes, it is important to document and benchmark final operation parameters in order to measure and verify energy savings. This also will provide a baseline for emergency system resets. The EMIS and user can monitor activity to verify expected operational and energy performance. The process can be seen in the graphic below.

Illustration by NREL

Institutions can sync the I2SL Laboratory Benchmarking Tool (LBT) with benchmarking data from ENERGY STAR Portfolio Manager and contribute to the tool's peer-group database of owner-submitted data from an ever-growing number of lab facilities. The tool allows institutions to:

- Compare the energy use of lab buildings with that of similar facilities in the U.S.

- Compare energy use intensity (EUI) based on square footage.

- Verify intended savings are met using data from the energy management information system.

Performance Management Plan

The performance management plan is developed to provide information, procedures, and tools to enable the facility to manage and maintain performance. The plan describes how activities of different stakeholders and departments are coordinated and integrated to manage performance. The plan provides a means to cost effectively maintain performance and ensure a return on investment. A beneficial management plan can include predictive maintenance, in which case a laboratory becomes proactive rather than reactive with maintenance. This management style relies on predictive fault and failure analysis. Predictive fault and failure analysis allows a software system to track when a fault might happen by alerting the facility. An example of this would be a vibration sensor on a bearing. Once the vibrations reach a certain level, the bearing is likely to fail so it should be inspected or replaced.

Deliverable: Building Management Plan

The building management plan (BMP) is the building's user's manual for how to operate and manage laboratory ventilation systems and exposure control devices. Most of the information comprising the BMP has been collected and developed during the assessment and optimization phases of the Smart Labs process. Materials contained in the BMP must be stored such that staff has access to the documentation, but controls are in place to limit the ability to modify contents without proper authorization.

Components of the BMP include but are not limited to:

- Individual building documentation

- Documentation for new baselines

- Images from BAS depicting system operating levels

- Information graphics and reports

- Accurate floor plans and system line diagrams

- Equipment inventories

- Maintenance database and schedules

- Lab ventilation risk matrices

- Up-to-date airflow specifications

- Control sequences and parameters

- Key performance indicators and metrics

- Standard operating procedures for tests, maintenance, and schedules

- Change management

- Training for stakeholders and staff

For continuity, the BMP places responsibilities on institutional positions rather than specific named staff to transcend changes or turnover of personnel.