Optimizing Laboratory Ventilation With Computational Fluid Dynamics

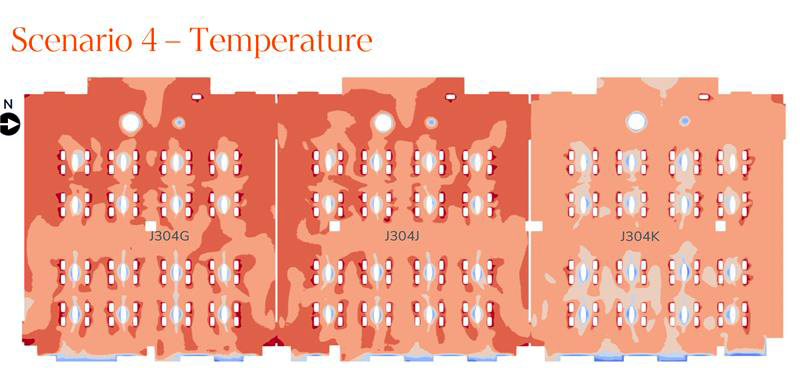

One of four scenarios ran showcasing 2D temperature distributions in laboratory. Graphic by CPP Wind Engineering Consultants

Ventilation plays a crucial role in laboratory efficiency, as it is one of the largest energy consumers in lab spaces. Computational fluid dynamics (CFD) is a powerful tool used to simulate and analyze fluid flow, heat transfer, mass transfer, and similar transport processes. Based on fundamental laws of physics, CFD has been widely applied in industries such as aerospace, automotive, and competitive sports.

CFD simulations provide time-varying, three-dimensional (3D) distributions of air velocity, pressure, temperature, chemical concentration, and plume dispersion. In laboratory environments, this information can guide heating, ventilation, and air conditioning (HVAC) design to help develop effective laboratory ventilation systems. Conducting CFD analyses in the early stages of lab design help identify potential issues and implement mitigation strategies to create safe, energy-efficient, and sustainable spaces.

Learn more about CFD on the HVAC Resource Map for Labs.

Computational Fluid Dynamics In Action

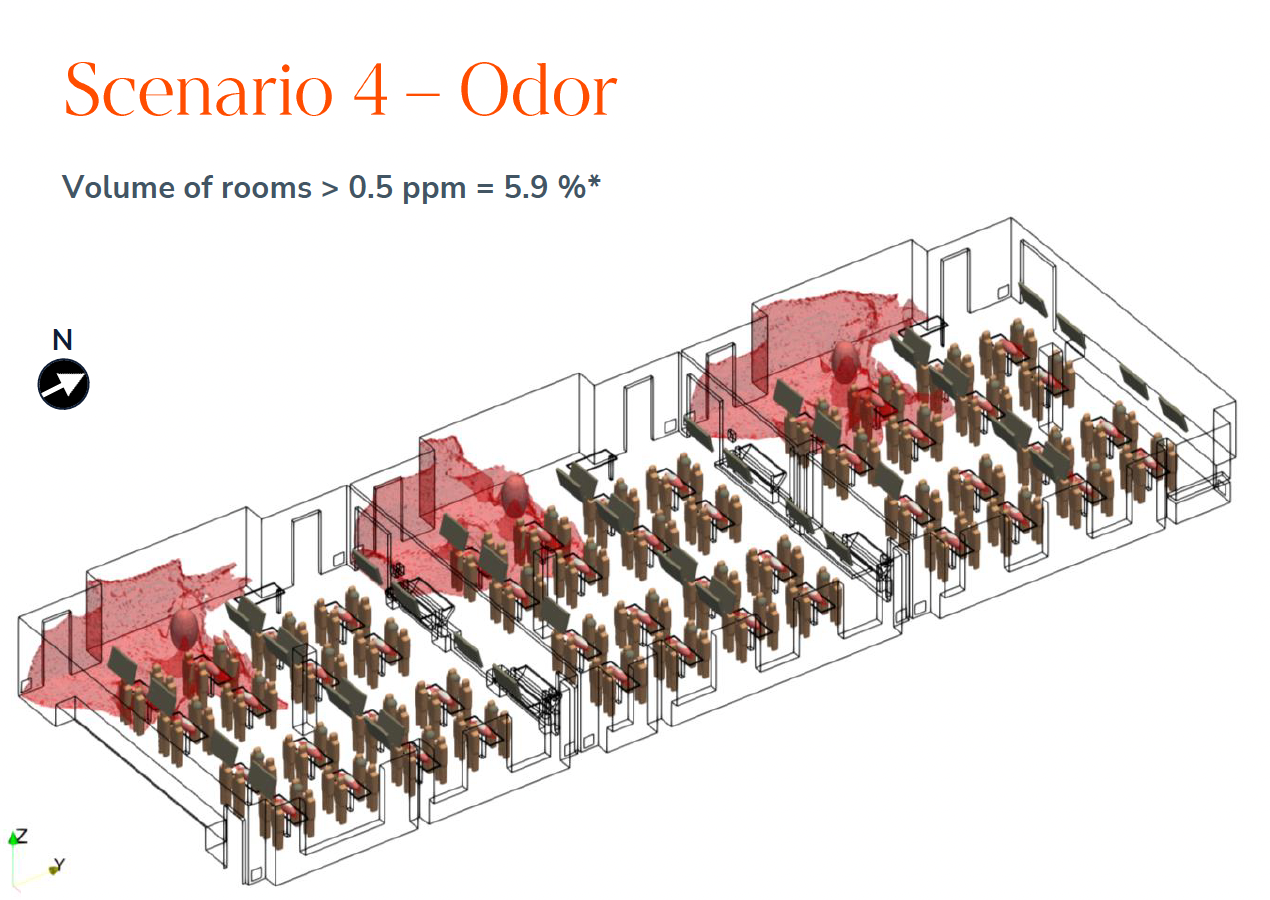

3D model showcasing the likelihood of occupants breathing formaldehyde in laboratory. Graphic by CPP Wind Engineering Consultants

CFD is a powerful tool for optimizing ventilation and ensuring the safety, comfort, and performance of laboratory environments. In a recent study conducted by CPP Wind Engineering Consultants, CFD simulations were used to visualize airflow and pollutant dispersion in a proposed addition to the James L. Voss Veterinary Teaching Hospital at Colorado State University in Fort Collins, Colorado.

The study evaluated formaldehyde concentration levels in three gross anatomy laboratories under different configurations, with particular attention to temperature, occupant health, odor dispersion, and airflow patterns. Four distinct simulation scenarios offered the design team vivid insights into how environmental conditions varied with occupancy levels and ventilation settings.

These simulations acted as a test of the HVAC systems under extreme use cases. The results revealed areas where odor control could become challenging, especially during full occupancy.

By visualizing how design decisions influence indoor environmental quality, CFD outputs became a critical component in guiding early-stage planning. These graphical representations helped identify areas where proposed systems might not meet performance expectations, reinforcing CFD’s role as both a diagnostic and iterative design tool in high-stakes environments like laboratories.

Computational Fluid Dynamics at NREL

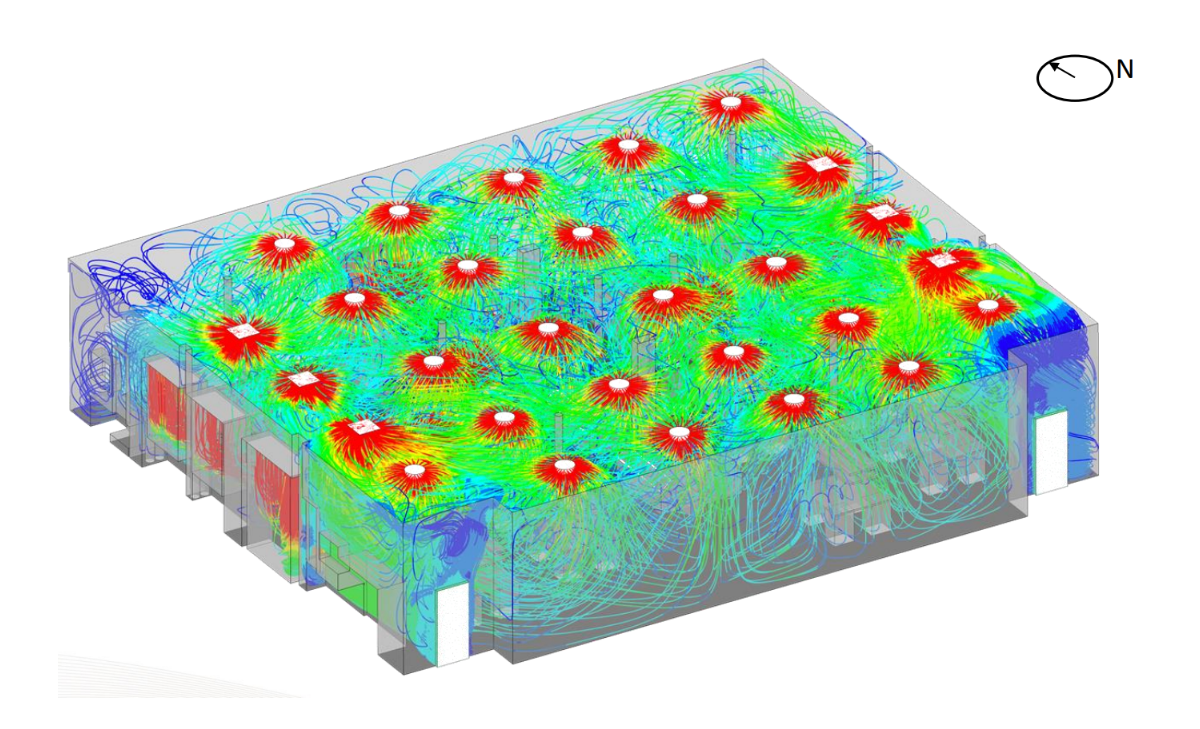

3D CFD model illustrating radial diffuser flow in the Research and Innovation Lab. Radial diffusers disperse flow over a large area. Air speed quickly slows down away from the diffusers and quickly speeds up near the fume hoods. Graphic by CPP Wind Engineering Consultants

The National Renewable Energy Laboratory (NREL) constructed a new Research and Innovation Lab facility at its main campus in Golden, Colorado, featuring two laboratory spaces. CPP Wind Engineering Consultants conducted an internal flow CFD analysis at the facility to optimize ventilation before finalizing the design.

The proposed laboratory room contained various supplies and exhausts, with air supplied by ceiling-mounted diffusers and exhausted through ceiling grilles, fume hoods, and other equipment. Several design iterations were tested to optimize airflow distribution. The analysis demonstrated that using laminar diffusers significantly improved ventilation effectiveness compared with two-way radial diffusers.

Conducting CFD analysis prior to construction played a crucial role in improving airflow control and energy efficiency, reinforcing the importance of evaluating multiple design options to optimize ventilation in research environments.

Computational Fluid Dynamics for Smart Labs

The Laboratory Ventilation Risk Assessment (LVRA) is a method that provides a systematic evaluation of risks associated with lab operations. It involves collaboration among facility and research staff, environmental health and safety professionals, and industrial hygienists. Ventilation demand establishes current airflow requirements, which can be used to design systems or evaluate existing performance. Quantifying the demand for ventilation supports flow reduction and energy conservation.

Visualizing three-dimensional airflow patterns and the flow path of contaminants helps identify areas where hazardous substances may accumulate. CFD analysis can also validate designs to ensure safety standards and regulatory requirements are met. By identifying potential areas of concern and correlating them with the risk assessment, mitigation measures can be implemented to reduce exposure.

A key factor in the Smart Labs process is the integration of technologies and best practices to improve lab safety and efficiency. CFD analysis can help to optimize the type and placement of advanced systems to monitor and control airflow, temperature, and contaminant levels. This enables adaptive ventilation strategies that respond dynamically to changing laboratory conditions, ensuring optimal safety and energy efficiency.

Use Computational Fluid Dynamics in Your Next Laboratory Project

CFD analysis is a transformative tool for both designing and enhancing laboratory spaces. By understanding the complexities of ventilation and airflow patterns, CFD analysis provides insights that can revolutionize the efficiency and safety of laboratory environments.

Key takeaways:

- Ventilation effectiveness is essential to protect laboratory occupants, support indoor air quality, and reduce energy use, making it a critical component of sustainable lab design.

- CFD simulations offer visual and analytical understanding of airflow behavior, temperature gradients, and pollutant dispersion. This helps design teams test HVAC systems and make data-informed decisions.

- Early-stage CFD analysis reveals vulnerabilities, offering opportunities to address potential comfort, odor control, and safety challenges, especially during high-use and fully occupied scenarios.

- Integrating CFD into Smart Labs initiatives enables adaptive ventilation, supporting dynamic airflow control and continuous monitoring in response to evolving lab conditions. This promotes both safety and energy efficiency.

- CFD is not just a design tool—it’s a resource for evaluating, iterating, and refining system performance in both new construction and retrofit projects.