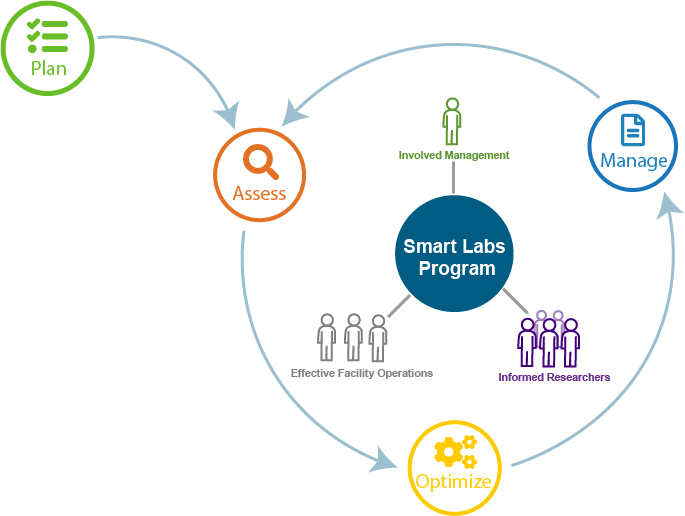

By this stage of the Smart Labs program, much of the initial, difficult work is out of the way. However, the Smart Labs team is by no means finished with their mission. High performance can be challenging to maintain, especially in laboratories, where changes in leadership, research staff, or best practices for safety and research procedures are common. In addition to the dynamic nature of laboratory environments, years of rigorous testing show that high-performance airflow systems lose up to 50% of their effectiveness within 5 years [1]. A key principle of Smart Labs is dynamic maintenance of operations, making a continuous cycle of management, assessment, and optimization essential in maintaining high-performance laboratories.

Conduct Ongoing Benchmarking and Analytics

Photo credit: Randy Montoya | Sandia National Labs

A traditional, statistical approach to improving the efficiency of heating, ventilating, and air conditioning (HVAC) systems no longer works as HVAC systems have become complex, non-linear, and dynamic. With the advent of smart equipment and digitization of HVAC systems, data analytics help with historical trending, pattern recognition and correlation between cause and effect of anomalies in system performance. Information analytics and fault detection can be combined to quickly identify and alert stakeholders to problems or opportunities to further improve performance.

Ongoing benchmarking and analytics can include:

- Advanced monitoring and control systems: implemented to monitor and verify proper operation and quickly identify and alert stakeholder to problems or opportunities to further improve performance

- Sensing chemicals in labs

- Measuring airflow

- Reporting the operating status of systems and components

- Real-time monitoring of HVAC system: Identify inefficiencies in the operation of HVAC systems, report them, and provide feedback to users.

- Other platforms to implement:

- Demand control ventilation systems

- Chemical sensor technologies

- Fire suppression and alarm systems.

- Benchmarking building performance through the I2SL Laboratory Benchmarking Tool to:

- Compare lab building benchmarks with other managed buildings or industry metrics

- Identify opportunities for further improvement,

- Track progress over time.

System analysis isn't limited to automation and control technologies. Real-time monitoring of HVAC system performance allows facility managers and maintenance staff to remain up to date and identify when performance indicators deteriorate. Regular assessments and walkthroughs determine if system components are hitting performance standards. As support to on-site inspections, monitoring is used to identify inefficiencies in the operation of HVAC systems, report them, and provide feedback to users.

Develop a Smart Labs Management Plan

The Smart Labs Management Plan consists of several components that will assist in coordinating the management of systems throughout the lab facilities.

Laboratory Ventilation Management Plan

The number of laboratory buildings, complexity of the systems, and magnitude of testing and maintenance efforts require a comprehensive Laboratory Ventilation Management Program (LVMP). A LVMP is a high-level, campus-wide guidance program that extends across all lab buildings. The content of this management plan is often developed during the Assess and Optimize phases of the Smart Labs process. The role of the LVMP is to define stakeholder responsibilities and establish lines of communication necessary for effective ventilation system operation. The LVMP provides the framework and process for managing laboratory ventilation systems so they continue to meet functional requirements of building personnel. Suggested LVMP content includes:

- Statement of purpose and goals

- Definitions of stakeholder responsibilities

- Lab ventilation design specifications

- Maintenance and routine testing protocol

- Building information and analytics

- Strategic plan for managing change.

Additionally, the LVMP should include standard operating procedures (SOPs) for:

- Monitoring operation

- Risk assessment

- Conducting routine tests and maintenance

- Evaluating the impact of change on system operation.

Following these SOPs will assist in identifying change and modifying the systems when necessary in order to facilitate ongoing efficient, cost-effective operation of the lab ventilation system.

Routine HVAC System and Controls Maintenance

The overall objective of the LVMP is to help ensure proper performance of the laboratory ventilation systems by providing a process for managing and maintaining their operation and use. Laboratory ventilation systems are comprised of numerous components, subsystems, and controls that must work together to satisfy the overall objectives of providing environments conducive to work, protecting lab occupants from overexposure, and operating efficiently. As such, the LVMP must provide a framework to test and maintain performance in an efficient and cost-effective manner.

To maintain desired system operation, each component must be performing as designed. An effective means to evaluate operation and performance is to sequentially challenge operation at the system and component level. In this manner, the operation of main components critical to ensuring proper operation of subcomponents are tested first, using a top down approach to verify and eliminate problems. This ensures the systems and components are working as expected and that accurate and precise results are obtained to eliminate erroneous conclusions and unnecessary retesting.

The critical test and maintenance tasks are conducted using a top-down approach according to the following order:

- Preventive and repair maintenance of air handling units, exhaust fans, and airflow control components including flow control valves and sensors, actuators, variable air volume (VAV) valves and thermostats, etc.

- System operating mode tests to challenge the systems over the operating boundary conditions.

- Lab environment tests and routine fume hood and exposure control device operation tests to ensure the devices are performing as required to meet applicable standards and performance criteria.

Lab Safety Surveys and Testing

Survey all labs, exposure control devices, and systems to verify their proper operation and identify changes in risk, demand for ventilation, or need to modify the labs, exposure control devices (ECDs), or operating specifications to accommodate lab occupants. Continual identification of trigger points for change, such as quick transitions of research needs in lab spaces, research involving chemicals with unknown bi-products and hazards, and changes in high-level management positions, allows the Smart Labs team to establish strategies for handling change effectively and efficiently without compromising the Smart Labs efforts.

Routine ECD Testing

ECDs should be tested as a component of the laboratory environment test. Test results are compared to standards and performance criteria to ensure the devices are performing and meeting defined, accepted minimum performance values.

Installation, operation, and maintenance of fume hoods—including testing—is guided by a variety of governmental and industry organizations including:

- Occupational Safety and Health Administration (OSHA)

- ASHRAE

- American National Standards Institute (ANSI)

- American Society of Safety Professionals (ASSP) (Formerly American Society of Safety Engineers [ASSE])

- National Fire Protection Association (NFPA).

Exposure control devices requiring periodic testing include, but are not limited to:

- Laboratory fume hoods

- Biosafety cabinets

- Snorkels or spot exhaust

- Laminar flow hoods

- Wet process benches.

Routine Laboratory Ventilation Risk Assessment

Because of the dynamic nature of laboratory research and processes, the Laboratory Ventilation Risk Assessment process should be re-visited annually or when hazards change in the laboratory. The frequency of these routine assessments may vary based on site-specific characteristics but is generally recommended annually. An assessment should also be conducted to identify potential changes to risk control bands resulting from physical modifications and/or changes to airflows within laboratory spaces.

Training

Catherine Hurley of Argonne National Lab at the Smart Labs for National Labs Workshop

Photo Credit: Rachel Romero, NREL

The LVMP is an organization-wide plan that encompasses all laboratory buildings and requires continuous training of personnel for successful implementation and operation. Ongoing training should be provided for anyone involved in operating, monitoring, or managing critical environment facilities including, but not limited to:

- Facility managers

- HVAC and controls engineers

- Building operators and maintenance personnel

- Environmental Health and Safety (EH&S) managers

- Lab managers, principal investigators, researchers, and other lab users.

Training topics need to be both general in nature for providing an overview of the LVMP process and employee responsibilities, and more specific for the subgroups to provide an additional level of detail relating to their processes and responsibilities. The following table includes suggested training.

| Personnel Type | Suggested Training |

|---|---|

|

EH&S Management Laboratory Manager Researcher |

|

Facility Management HVAC and Controls Engineer Maintenance Technician |

|

Laboratory Equipment

Photo credit: Oak Ridge National Laboratory

Developing a plan for freezer management and other plug loads, lighting, and other research equipment allows the Smart Labs team to identify equipment that may be due for an upgrade. Rather than allowing an inefficient freezer to continue using excessive energy, periodic maintenance and assessment allows site operation staff to identify problems in early stages and repair equipment or perform upgrades, when necessary.

Periodic maintenance also allows facility operations staff to keep all building systems up to date with current best practices. Smart Labs are dynamic spaces; as a result, best practices are also dynamic as people develop better ways to optimize safety and laboratory performance. Refer to the Assess phase for detailed guidance in continued assessment of building systems to maintain high-performance laboratory facilities.

Resilience

Photo credit: Randy Montoya | Sandia National Labs

Developing a plan for continuity of operations ensures that lab facilities will be prepared to maintain operation of critical facilities and prevent damage to property, equipment, environment, and people in emergency situations including extended power outages, global pandemics, or government shutdowns. Large institutions are required by the Federal Emergency Management Agency (FEMA) to have a Continuity of Operations Plan for essential operations. FEMA provides templates and training to guide institutions in developing plans for telework and continued operations for emergency situations.

Suggested components to include in a comprehensive resiliency plan are listed below.

Schedule for monthly generator tests: Regularly testing back-up energy generation systems ensures continuity of operations is supported in the event of gaps in energy services due to natural disasters, preventative shut-downs, organizational degradation, or technical failures.

Freezer management plan: Determine a plan for freezer management in the event of service failure to minimize setbacks in research and damage to important materials that require continuous cold environments.

Plan for emergency laboratory closures: In the event of extended power outages, global pandemics, or government shutdowns:

- What does the institution need to do to have a plan in place?

- What shutdown protocols are in place to minimize effects on laboratory operations and maintain critical operations in the event of extended power outages or closures (i.e. more than 24 hours)?

- How will the institution handle potential for flooding in basements where vital building system equipment is housed?

Organizational protocol: Determine the responsibilities of personnel and groups in ensuring each component of the plan is formed and updated on a regular basis to maintain relevancy.

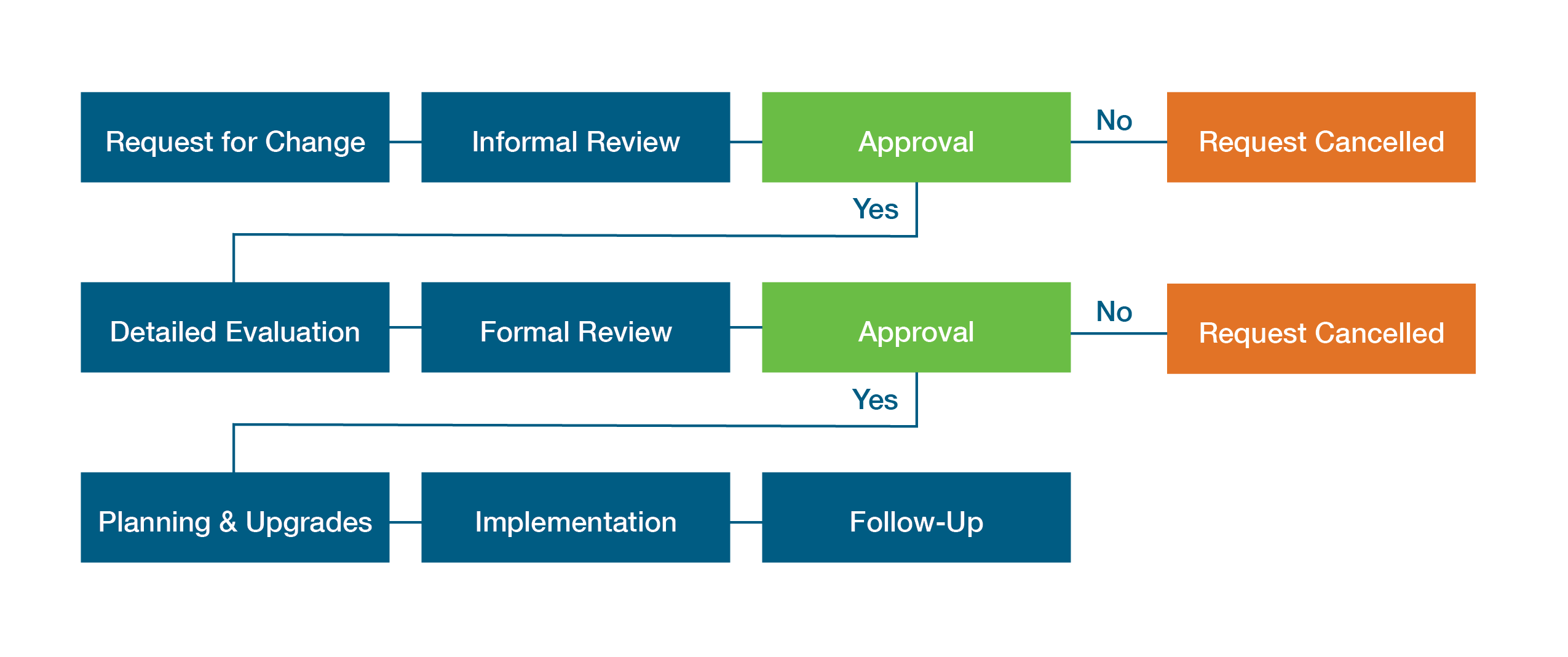

Manage Change

Stakeholders are responsible for conducting change managements procedures so that building systems can be added, updated, or altered to fit the needs of laboratory personnel. These procedures should identify who is responsible for coordinating or managing the changes and the process that the laboratory will go through to accept these changes. The figure below represents a possible change process. In response to changes in personnel, risk profiles, or the need for lab or system modifications, the team will review documentation to update documents and recommission systems as necessary.

The foundation of a successful Laboratory Ventilation Management Program (LVMP) is management of change. An effective change management program ensures the safe and efficient operation of laboratory buildings by providing the steps necessary to control appropriate improvements and prevent uncontrolled changes to the ventilation systems.

Labs are dynamic environments due to personnel turnover and experimental procedures and materials. Some trigger points for change include:

- Space planning

- Lab inspections

- Routine certifications testing

- Changes in chemical inventory

- Changes in chemical procurement

- Changes in hazardous waste records

- Changes in personnel

- Change in lab risk profile

- Changes to key performance metrics

- Need for modifications to lab HVAC systems or controls.

After completion of a change, all associated documentation such as drawings, test results, and risk ratings must be updated to reflect current conditions.

Deliverable: Smart Labs Performance Reports

Photo credit: Andrea Starr | Pacific Northwest National Laboratory

Smart Labs performance reports are periodic reports that update important stakeholders on the overall performance of the Smart Labs program. The reports should highlight successes of the program’s efforts and plans for future efforts. Suggested contents include:

- Team or staff involved and levels of involvement

- Policy and procedure changes

- Highlights of safety improvements

- Optimization measures or building upgrades, especially those that employ innovative uses of technologies

- Energy consumption reports for each laboratory building

- Highlights of significant cost savings and energy reductions

- Lessons learned from efforts to date

- Plans for future improvements.

Conclusion

The Smart Labs Toolkit describes the tasks required to deliver successful projects. Achieving satisfactory results requires investment and a long-term commitment to ensure proper performance that extends throughout the lifecycle of the building. With proper leadership, allocation of sufficient resources, and coordination of activities, organizations can assess, optimize, and manage high performance laboratories and critical control environments. The benefits of proper implementation of Smart Labs are numerous and enable organizations to mitigate risk, reduce waste, and achieve more sustainable facilities.

- Plan

Build a team of lab stakeholders

Profile buildings to prioritize efforts

Develop a strategic plan for evaluating lab buildings. - Assess

Conduct in-depth audits of laboratory building systems

Focus on the ventilation systems

Develop a scope of work for system optimization. - Optimize

Execute meaningful projects with demonstrable payback

Develop a building management plan outlining dynamic management to further optimize operations. - Manage

Implement a laboratory ventilation management plan

Apply lessons learned in improving additional facilities on the campus.