The University of Chicago's Smart Labs Program Reduces Energy Use and Improves Building Performance at the Ellen and Melvin Gordon Center for Integrative Science

The University of Chicago's Ellen and Melvin Gordon Center for Integrative Science (GCIS) is among the University's largest and most complex buildings with the majority of the 472,000 square foot building dedicated to high-acuity research. GCIS is also the largest energy consumer on campus, accounting for over 15% of usage. As such, the building was identified as a prime candidate for the Smart Labs program. This ongoing safety and sustainability initiative is a collaborative effort across several UChicago departments, including Energy Services, Building Engineering, Building Automation, the Office of Research Safety, Physical Sciences Division, Biological Sciences Division, students, and Information Technology. The Smart Labs program at GCIS has reduced energy consumption, improved occupant comfort, improved lab safety, and increased the resiliency of this critical building.

The effort started with a detailed study of the building systems, including functional testing of key mechanical components and review of laboratory airflow setpoints, as part of the UChicago Preventive Maintenance and Commissioning program. The building presented a unique challenge, since its critical and highly sensitive research environments require tight temperature and humidity control with large amounts of ventilation air. While strengthening those operating environment imperatives, the project team was able to identify and implement 13 energy conservation projects that included optimization of the heat recovery system, steam trap replacements, intelligent control of office airflow in accordance with industry-standard safety guidelines, and optimization of the chilled water plant. In addition, deep equipment maintenance and central building automation system control programming improved system operation and occupant comfort.

Given its size and complexity, GCIS has a vast repository of building operational data available for analysis. To make the most out of this data, the team installed a monitoring-based commissioning (MBCx) system as a pilot project for the campus. Using advanced algorithms to analyze building data, this system can identify energy saving opportunities in real-time. The MBCx system compiled fume hood usage data, identified inefficiently functioning equipment, and provided system-level breakdowns of energy use for measurement and verification.

Prior to initiating the Smart Labs program, GCIS experienced challenges in meeting strict humidification requirements at cold temperatures due to steam system capacity limitations. Research humidification requirements grew over the years at GCIS eventually leading to a situation where humidification requirements could not be met during very cold days. A cross-functional team met to develop both short- and long-term actions to improve system performance to meet the critical research requirements. In the short-term, the team focused on energy efficient behaviors such as the "Shut the Sash" program, reductions in minimum humidification levels where viable, increased maintenance of humidifiers and air handling equipment, increased steam pressure, and optimization of ventilation rates.

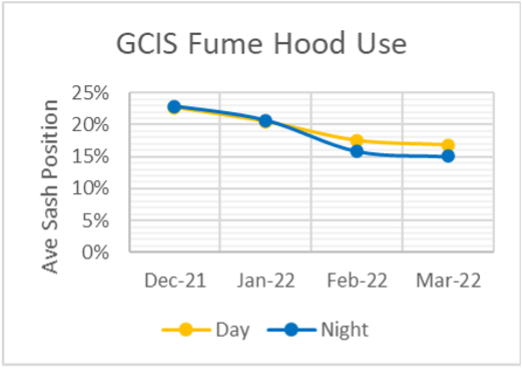

The "Shut the Sash" program improved fume hood use. Energy engineers aggregated sash position data into monthly averages and shared the data with building managers and department heads to communicate with the researchers. As a result of this initiative, the average fume hood sash position decreased 30% from its peak, improving lab safety and reducing energy consumption. A student-led building-wide competition will be launched to reward top performers and further incentivize safe and efficient fume hood use.

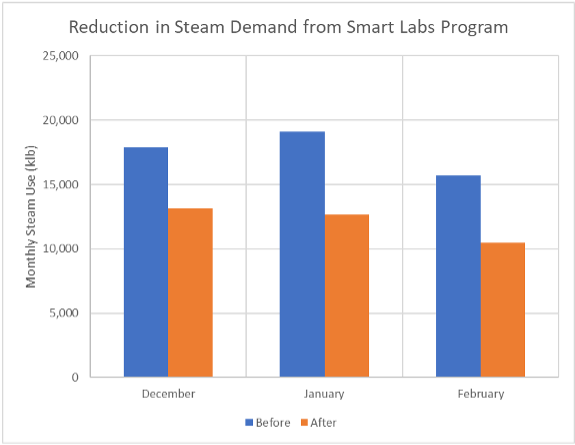

Energy conservation and behavioral efforts implemented by the Smart Labs program improved building humidification performance through a reduction in steam use by over 30% during winter months. When combined with improvements in the delivery of steam to the building, these efforts significantly improved building humidification performance in 2022.

The Smart Labs initiative also investigated water savings opportunities, which led to an innovative water recovery project. Each summer, the building's cooling system dehumidifies the incoming laboratory makeup air for occupant comfort and to maintain precise environmental requirements for research. During peak conditions, system flow exceeds 70 gallons per minute; this is equivalent to 35 showers operating at the same time! As is standard design for these systems, the condensate was previously sent to the city sewers. A new system was installed to recover this condensate, using a series of pumps and piping to send water from eight laboratory makeup air systems in the basement to the rooftop cooling towers. The condensate recovered during warm, humid weather partially offsets the water demand of the building's central cooling plant and reduces water consumption by nearly 3.3 million gallons per year.

The Smart Lab initiatives at GCIS improved the facility in many ways:

- Laboratory safety benefited through improved fume hood use while occupant comfort improved through optimizing equipment and calibrating sensors.

- Reduced equipment loads increased available capacity and improved system performance during extreme weather conditions.

- Energy savings reduced total building energy use intensity by over 13% at the meter, corresponding to a reduction in greenhouse gas emissions of 3,140 metric tons eCO2 per year—the equivalent of eliminating carbon emissions from 361 homes.

These improvements will continue to be measured and managed in line with the Smart Labs process. Researchers should be constantly looking for new methods and opportunities to optimize building performance.

Interested in learning more on how you can manage your own Smart Labs facility? Check out these resources: