Identifying Smart Lab Opportunities at Pacific Northwest National Laboratory

Pacific Northwest National Lab (PNNL), located in Richland, Washington, has roughly 4,500 scientists, engineers, and nontechnical staff on hand and operates a budget of $960 million. Across the campus, PNNL has over 40 laboratory buildings covering research from marine to radiochemical sciences and engineering. With a facility this size, PNNL's sustainability team is focused on reducing water use and energy consumption and helping the U.S. Department of Energy reach its goals to reduce greenhouse gas emissions from building energy consumption.

One strategy that PNNL implemented to improve building efficiency was establishing a Smart Labs program to improve energy management best practices and perform technological upgrades.

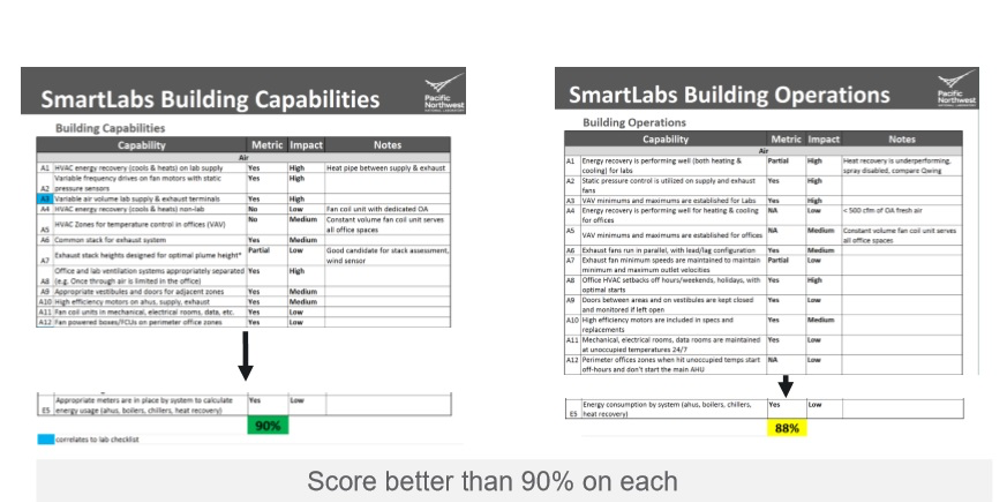

Working with Emory University, PNNL developed a Smart Labs checklist to help target high energy-consuming buildings and identify gaps and opportunities. The checklist analyzes performance in the following categories: air, water, controls, lighting, and energy.

Using these categories, the checklist looks at the building's capabilities and operations. The capabilities section of the checklist examines what features the building already has, while the operations section dives into how the systems are used and operated. The checklist also allows building operators to compare review buildings side by side for projects.

Example of PNNL's Smart Labs checklist.

Using this checklist as guidance, PNNL evaluated its General-Purpose Chemistry Laboratory and performed the following improvements:

- Adjusted occupancy sensors

- Updated building automation system (total exhaust, room volume)

- Disabled dehumidification

- Set mechanical/electrical rooms to unoccupied setbacks 24/7

- Programmed chilled water differential pressure reset

- Realized the gas meter was installed incorrectly (reading 2.2.7x lower)

- Set back air rate change during unoccupied mode

- Fixed heat pipe coil (unlevel, evaporative cooling)

- Setback corridor to ~4 air changes ever 24/7.